On the experimental farm at the University of Florida’s Southwest Florida Research and Education Center, the fourth revolution of agriculture is in high gear.

Drones fly over citrus groves, counting and categorizing trees.

On the ground, robotic arms collect pests from tree branches to determine which trees need to be treated.

Multispectral imaging collects spectral data from tomato plants, the better to detect diseases like target spot and bacterial spot before they spread throughout a field.

Ground-based remote sensing equipment scours groves, up one row and down the next, to survey for green vs. ripe fruit.

Machines straddle rows of peppers, sensors spotting and spraying weeds only as they encounter them.

And behind the scenes a new cloud-based software called Agroview sucks up all the data, analyzing it and synthesizing it into chunks that scientists — and farmers — can use to make better decisions.

Artificial intelligence, robotics, automation, big data analytics, the internet of things. This is no doubt the fourth agricultural revolution. We are going to see these technologies in the field very, very soon.”

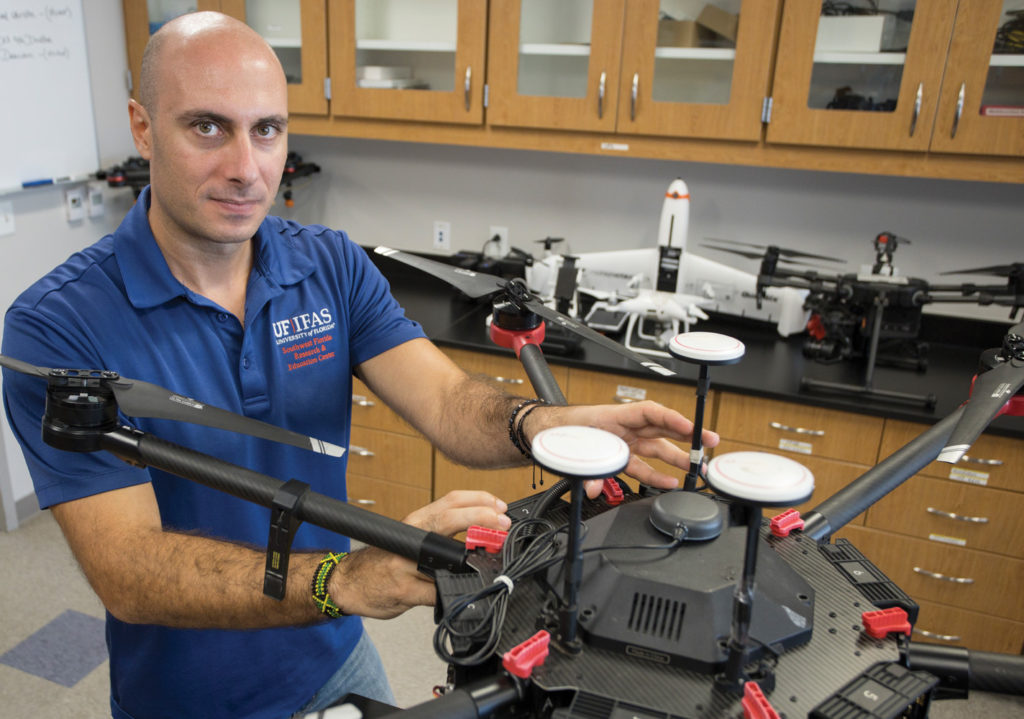

— Yiannis Ampatzidis

UF agricultural engineer Yiannis Ampatzidis says artificial intelligence — the convergence of new tools for data collection with cloud computing to analyze the explosion of information — is changing the face of agriculture in a way that is nothing short of revolutionary.

“Revolution is the perfect word,” says Ampatzidis, an assistant professor of agricultural and biological engineering in Immokalee at the SWFREC, a part of UF’s Institute of Food and Agricultural Sciences.

“Artificial intelligence, robotics, automation, big data analytics, the internet of things. This is no doubt the fourth agricultural revolution,” Ampatzidis says. “We are going to see these technologies in the field very, very soon.”

In the first agricultural revolution, mechanization — tractors, harvesters and such — changed life on the farm. In the second, chemicals — fertilizers and pesticides — drastically increased yields. In the third, genetics produced hybrid plants, boosting yields yet again. What will artificial intelligence capabilities do for agriculture in the fourth revolution? A better question, Ampatzidis says, is what won’t they do?

Todd Motis, a manager at Chemical Containers, an agricultural equipment designer and manufacturer, says the scope of research at UF and the SWFREC is large.

“What they’ve already done is just the tip of the iceberg,” Motis says.

King Citrus

The AI explosion was in progress in 2020 when J. Scott Angle took the helm as the new vice president for agriculture and natural resources. He has been impressed at the scope of AI applications, research and outreach at UF.

“AI is the next technology that will change agriculture in a profound way,”

Angle says.

Automating even basic chores pays off, Angle says, and Ampatzidis says that is especially true for citrus, Florida’s signature crop. For example, just creating a tree inventory for a grove is expensive and time-consuming.

“Before automation, an inventory required driving throughout a field with two people, one looking left, one looking right, and they would have counting devices or clickers, and if they see a big tree they click one clicker, and if they see a small tree they click another one,” Ampatzidis says. “They need to mindfully count.”

Mapping systems, like Google maps, help, but they are not precise enough and are often five to 10 years old.

“Even if you open Google maps, imagine you have a field with 50,000 trees. Can you count them all?”

The clickers also don’t register all the variations in sizes, or gaps between trees. Manually counting trees on just 1,000 acres can cost up to $14 an acre. Using drones, the time can be reduced by 90 percent and the cost by 60 to 70 percent, Ampatzidis says.

Once the drone images are uploaded into Agroview, the grower can access much more than just a tree count. Agroview processes and analyzes the visual images to provide information such as tree height, canopy size, stress condition, and gaps where trees need to be replanted. The grower can also search for specific categories, for example, all the trees less than 7 feet tall.

A ground-based system that can be paired with Agroview can detect and count fruit, even immature green fruit, which is difficult because green fruit is the same color as the leaves. This helps the grower monitor growth, predict yield and prepare for harvests. Agroview can also determine plant nutrient concentration and develop fertility maps that create management zones for precision agriculture applications.

Growers, understandably, are eager to get their hands on Agroview, which UF Innovate named Invention of the Year.

Angle says AI will leverage the capabilities of other technologies. For example, mechanization has been around a long time, waiting for the technologies that will make machines smarter. And smart mechanization will become even more important in the face of labor shortages, he says.

“We’ve always had the mechanical part, let’s say, for picking a peach,” Angle says. “We’ve got claws that can reach out, grab it, pull it off the branch, throw it into a bin. The problem is, is that peach ripe, ready to be picked? That’s a hard question.

“A human can determine that easily, but a robot can’t. Secondly, when you grab that peach, if it’s ripe and you put too much pressure on it, you’ll squish it. And if you don’t apply enough pressure, it’ll drop out of the claw.

“So that’s a question for AI to solve for us. Every peach will become a specific calculation,” Angle says. “I think in the next couple of years, we’re going to see robots in our orchards and our groves harvesting a lot of our crops.”

What AI is going to do is open up a tremendous amount of knowledge, but also decision- making based upon that knowledge, to everyone. It’s a great equalizer when it comes to agriculture, forestry and natural resources.”

— J. Scott Angle

UF Vice President for Agriculture and Natural Resources

Leading with AI

Angle agrees with Ampatzidis about the revolutionary nature of AI in agriculture and sees AI as having perhaps more impact in agriculture than in some other arenas.

In manufacturing, for instance, large companies like automakers deploy advances as they occur. Large agricultural companies do as well. But while there are no mom and pop automakers, there are thousands of mom and pop agricultural producers. Angle says AI will level the playing field for all producers, big and small.

“Right now, sophisticated information is generally only available to the largest producers, the biggest corporate farming and forestry operations, because they can afford it,” Angle says. “Smaller producers have not had access to a lot of this. What AI is going to do is open up a tremendous amount of knowledge, but also decision- making based upon that knowledge, to everyone. It’s a great equalizer when it comes to agriculture, forestry and natural resources.”

Agronomy department Chair Diane Rowland, director of the Center for Stress Resilient Agriculture, says putting AI into the hands of even the smallest farmers is the goal of a new, four-institution grant from the National Science Foundation. Rowland and David Arnold, of UF’s Electrical and Computer Engineering department, are UF leads on the $26 million grant designed to help farmers grow more crops with fewer inputs, such as water, chemicals and energy.

Rowland is leading the agricultural sensor systems team, and she says a collaboration that began four years ago with engineering researcher Alina Zare is a sign of the benefits of AI. In her agronomy lab, her team was looking at root function and wanted to move beyond understanding the architecture of crop roots.

“We were using the tools we have traditionally used, and I knew that we were not gathering the information in as complex a way as we could,” Rowland says.

The results were amazing, she says. Researchers had been able to see differences with their eyes, but unable to statistically quantify how the differences occurred, the minute changes in the process of a plant transitioning from a well-watered plant to an over-watered or under-watered plant, for instance.

Rowland says last year’s $70 million partnership with NVIDIA, which includes the gift of one of the fastest supercomputers in academia, will change logistics for researchers, and that will change research outcomes.

“For example, in our root work with Alina, we had 17,000 images that had been hand-traced on a computer. You can imagine the person hours if we added them up,” Rowland says. “I envision the NVIDIA computing power allowing us to basically crunch all of that very, very quickly. So we should be reaching solutions at a much faster pace.”

We (in IFAS) don’t understand the machine learning side, and they don’t understand the biology side, but when you’re looking at the same problem together, each side brings different viewpoints. And so in some ways the misunderstanding of one side actually brings new ideas to the group as a whole. That process is the key to making these advances. It has to be done together.”

— Diane Rowland

The collaboration between the College of Engineering and UF/IFAS has also been fun to watch, she says.

“It’s really amazing to watch students. We bring in engineering students and bring in agronomy students, and they sit at a table and look at a problem together. We (in IFAS) don’t understand the machine learning side, and they don’t understand the biology side, but when you’re looking at the same problem together, each side brings different viewpoints. And so in some ways the misunderstanding of one side actually brings new ideas to the group as a whole,” Rowland says. “That process is the key to making these advances. It has to be done together.”

Angle says the 12 UF/IFAS research and education centers throughout the state and the extension offices in all 67 counties will allow AI to quickly get into the hands of the producers that can use it and eventually onto Floridians’ kitchen tables.

“We have regular communication with farmers and foresters and natural resource managers that have the problems AI can address,” Angle says. “I think it will show up a little faster than most people think. I think we’re just a couple of years away.

“It will greatly expand access to information, so that what GM and Boeing have access to today, a homeowner will have access to in the future. That’s why I call it the great equalizer.”

Row Crops

In Florida’s fields of tomatoes — the state’s third-largest crop — drones are the newest workhorses.

Using multispectral and hyperspectral imaging — far more sophisticated than inspection by the human eye — drones outfitted with cameras can measure reflected solar radiation to detect diseases. Ampatzidis and UF plant pathologist Pamela Roberts found the system could identify two scourges of tomatoes — bacterial spot and target spot — with around 90 percent accuracy.

In a 20-minute flight, about 60 acres of tomato fields can be scanned, a huge time savings for growers, who otherwise would manually have to check for the disease row by row.

The system also detects disease at a very early stage, which is critical for growers, and can distinguish between bacterial spot and target spot, so the right chemical — and the right amount of chemical — can be used. Based on the data gathered, Ampatzidis says the team also has developed AI models to predict diseases in other vegetable crops as well as tomatoes.

The diseases are chronic, occurring every season, Roberts says, and the two together can cost tomato farmers about $5 million a year.

Roberts has been working with tomatoes for 20 years and said a solution like this is long overdue.

Another technology is being tested on peppers. Ampatzidis calls it a smart sprayer because the apparatus travels above a row and, using machine vision and AI, sprays herbicide when it spots a weed, such as portulaca. It doesn’t spray when it spots non-target plants, like the peppers themselves or sedgegrass. The smart sprayer saves both money and chemicals, helping the farmers and the consumers who buy the produce.

Rowland says technologies like hyperspectral imaging also help in harvesting crops like peanut.

“Peanut grows underground, so predicting when it should be harvested is very difficult. With a corn plant, you can go out and take a look at the ear and say ‘yeah, it’s ready,’ but with peanut you can’t do that,” Rowland says.

When peanut growers dig their crop, they go through a painstaking process to determine what is mature and what’s not, removing the outer skin of the hull and looking for colors — white, yellow, orange, brown and black — to see if a pod is mature.

“It’s a huge amount of work and laden with error,” Rowland says. “But with hyperspectral imaging, we can tell which pods are mature or not.”

Hyperspectral imaging can also be used in a shelling plant to detect peanuts that are hiding aflatoxin, a fungus, underneath the hull. Aflatoxins are associated with liver cancer, so keeping aflatoxin-contaminated peanuts out of the food supply has health benefits.

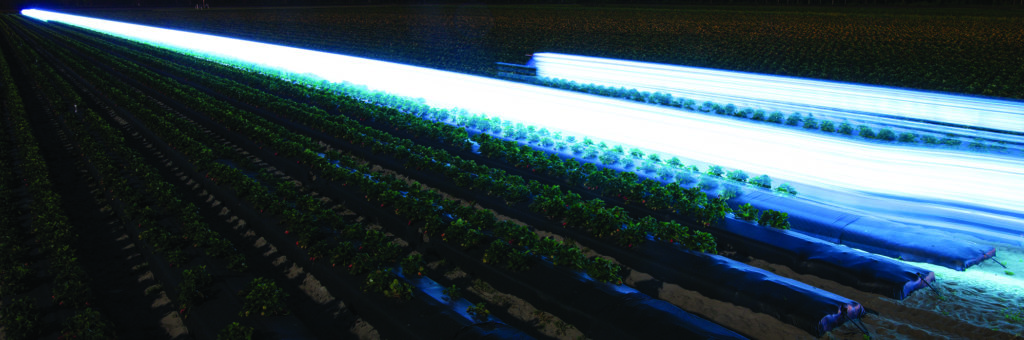

Ampatzidis says UF agricultural engineers recently started working with a company in Tampa, Harvest Croo Robotics, on an autonomous robotic harvester of strawberries, a crop with such severe labor issues that some growers have considered not planting as opposed to planting and letting unpicked crops rot in the fields.

“We need to develop these technologies and use artificial intelligence to be competitive and compete in a global market,” Ampatzidis says.

strawberry farm near the Gulf Coast Research and Education Center in Balm.

Beyond the Farmers’ Almanac

Agroview, a cloud-based application, aggregates data from drones, satellites, sensors and imaging equipment. Agroview can take disparate information and produce maps of fields or groves, showing trees and gaps between trees, tree height, canopy size and leaf density. It can also estimate plant nutrient concentration and — in the near future — predict yield and fruit quality. In row crops, it can also show spacing and overlay data about where pests have been detected, allowing it to create a tool called a prescription map, which offers detailed instructions on where to apply fertilizers and pesticides to best effect. Agroview is now on generation 4, and Motis says it provides a foundation for further development.

Prescription mapping and smart sprayers are not only good for growers’ budgets, they are good for the environment, too, because reducing pesticides and fertilizers means less chemicals seeping into Florida water supplies.

“With this system, we will be able to treat every tree on a per-tree basis,” says Motis, who worked in turfgrass, ornamentals, citrus and other crops before joining the family business.

“Every tree, every vegetable plant will have its own name. For the first time ever, we will be able to treat in a way that the tree utilizes every nutrient, and that means less runoff into water supplies. Cost savings may drive sales, but the best reason to do this is to protect our water.”

Motis sees the potential to develop industry-specific technologies as well, and Ampatzidis agrees.

Ampatzidis says the AI revolution will act as a multiplier effect for all the previous agricultural revolutions. For example, drones can collect phenotype data, which can be fed into software to find the trees and plants that perform the best from a genomic standpoint. He says he is looking forward to collaborating with plant geneticists.

“The strength of UF is that we have all these faculty from different disciplines that can help us to better develop these AI models,” Ampatzidis says.

In the Fourth Agricultural Revolution, soil and water and weather still matter. But data — and data-based decision-making — is king.

Source:

Yiannis Ampatzidis

Assistant Professor of Agricultural and Biological Engineering

Southwest Florida Research and Education Center

Hear the Story

The audio version of this story is available on our YouTube.