Not every microscope is created equal. The trick is finding the right one, and sometimes that means starting from scratch.

“All of our microscopes start with us having a biological question in mind without having the tools or technology to address that question,” says University of Florida optical engineer and neurobiologist Jim Strother.

He’s building and customizing his own microscopes with technology developed in his lab to explore how single cells become whole animals, how tissues recover from injury, and how nerve cells are wired together.

These types of research questions tackle extremely dynamic cell processes that require equally fast fluorescent imaging technologies. Traditional microscopes, sophisticated as they are, just can’t keep up.

Most fluorescent microscopes operate like a 3D laser printer that prints one line at a time as it builds a 3D object — a beam of light scans across an imaging plane, then passes through tissue to scan the next imaging plane, and on and on as it reconstructs a picture. It can take precious seconds to move light beams and change imaging planes and refocus. Blink, and you might miss something really cool.

A lightsheet microscope like the one Strother is building can speed things up by passing a whole sheet of light through tissue and scanning entire imaging planes rather than one pinprick at a time, like a 3D printer that could print entire layers at once with each pass.

But even traditional lightsheet scopes aren’t always fast enough.

3D reconstruction of a comb jelly taken on the new lightsheet microscope at the Whitney Lab. Comb jellies are one of the earliest animals on Earth to possess both neurons and muscles and offer key insights into animal evolution.

It’s possible to increase imaging speed even more by introducing a lens in the microscope’s body that changes shape with electrical inputs, much the same way the lens in the human eye changes shape and refocuses with tiny muscle movements. Lightsheet microscopes that use deformable lenses like this bypass the slow process of moving a lens to a new position and refocusing. The drawback is that images tend to blur when the focus changes, limiting the real-world usefulness.

To get around these limitations, Strother worked out a theoretical framework describing why images would blur and developed optical design rules for a new lightsheet microscope. His soon-to-be patented technology introduces an intermediate focal plane in front of the deformable lens, a shift which helps the sample image remain sharp as the scope’s focus changes.

“With this system we should be able to improve imaging speeds by an order of magnitude,” says Strother, making it so scientists at the lab can begin tackling even tougher research questions.

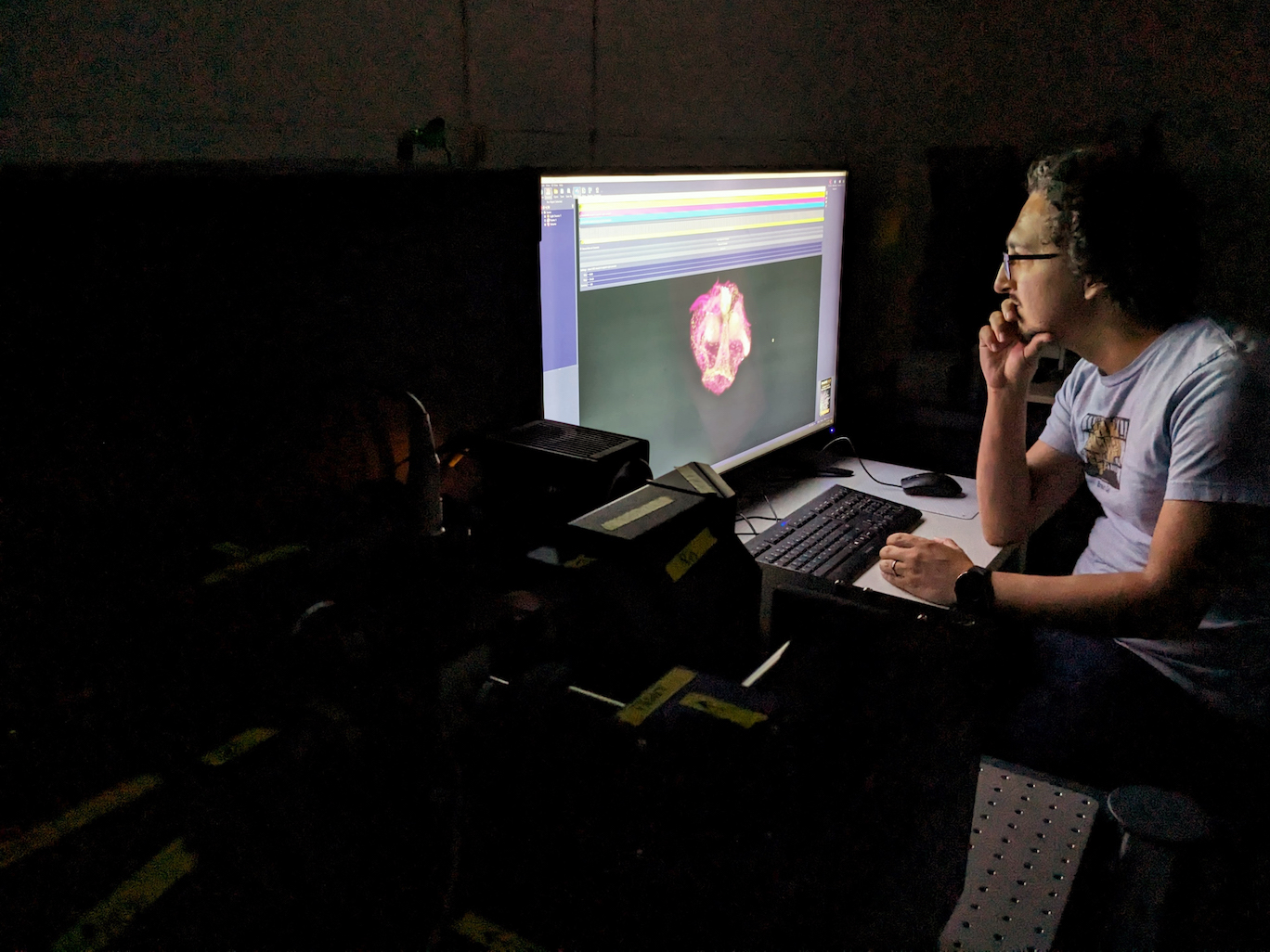

PhD student Dorothy Mitchell prepares a sample for the new lightsheet microscope.

Strother’s group is part of the UF’s Whitney Laboratory for Marine Bioscience, a research institute specializing in basic science and marine organisms, including warty comb jellies, starlet sea anemones, colonial hydractinia, upside-down jellyfish, and segmented sea worms. These organisms tend to be understudied in science circles, meaning Whitney researchers often must adapt existing technology to get at their research questions.

“Everyone knows you need to have the right tool for the job,” says Mark Martindale, director of the Whitney Lab and microscopy enthusiast. “High resolution optical imaging is vital to the scientific success of virtually everyone here.”

Making too many modifications on an existing microscope introduces extraneous constraints, whereas something built from scratch is only constrained by the laws of physics. There’s freedom in making that choice and exploring new frontiers in science, even if there’s an element of risk.

“When you build any sort of custom instrumentation, you’re on the wrong side of the economy of scale,” Strother says. Every piece must be perfectly shaped, otherwise it could cost another $1,000 to fix.

“You don’t want to build the microscope twice,” Strother says. “You make sure it’s designed right the first time.”

Sometimes a commercial solution already exists and the research question doesn’t require drastic adaptations. So why reinvent the wheel?

Earlier this year, Strother ordered a new commercial lightsheet microscope and had it shipped from Germany. The computer controlling this microscope can rotate samples to take images from multiple perspectives and with different wavelengths of light, improving resolution and limiting light damage.

“Instead of getting snapshots, we can watch how cells are migrating or dividing during the entire developmental window,” Strother says.

Strother’s new microscopes will make up the core of the Whitney Lab’s new Center for Biological Imaging and Discovery and serve as a resource to train future scientists. The center is funded by donors who have joined the lab to spearhead new imaging technology and training initiatives. To that end, Whitney Lab has acquired three fellowships to support graduate students who will continue developing and applying new optical technologies in their PhD studies. These researchers, in turn, will assist the Whitney community and visiting scientists eager to push the boundaries of physics to answer new and exciting biological questions.

When the new imaging center opens — hopefully by the end of this year — the Whitney Lab will become even more of a regional powerhouse for modern imaging. Then the fun can really begin.

“We’ll be one of the most high-tech marine labs in the country,” says Martindale. “We look forward to collaborating with other scientists and opening whole new vistas of research that were previously impossible.”

Story by Brent Foster, photos by Heather Krumholtz